Guangdong Seeney Technology Co.,Ltd Booth No.2611

Company Profile Guangdong Seeney Technology Co.,Ltd. is a professional machine vision solution supplier. After years of research and technological innovation, using our Seeney vision system, software algorithm and sensor technologies, we have successfully provided comprehensive vision solutions for great corporations of magnetic core, chips, IC, conductors etc. Relying on the independent research and innovation abilities, we have resolved key technical problems of various appearance defects on different components, such as scratch, crack, stain, and even die crack. With our personalized vision detective solutions, our customers have greatly improved their product quality, reduced the labor costs and then acquired competitive advantages in the global market. We have always been adhering to the principle of ”°Innovation first, Quality first and Customer first”±. We will make full use of our advantages on the product design, technical innovation and the hardware facilities to establish an world outstanding brand in the field of vision intelligence.

Exhibits 1. High speed detector

Advantage: High effective to test defects such as chipping and corners, printing marks, surface damage, surface unevenness, printing marks, printing sagging, extension, black speck, impurities, oxidation, abnormal color, etc.

2. standardizing machine

Advantage: High effective to identify defects such as cracks, chipping, dirt, blistering, scratches, missing corners, watermarks, deformation, shape (length, width, and height) etc. Production speed: 35000-180000 pieces/hour.

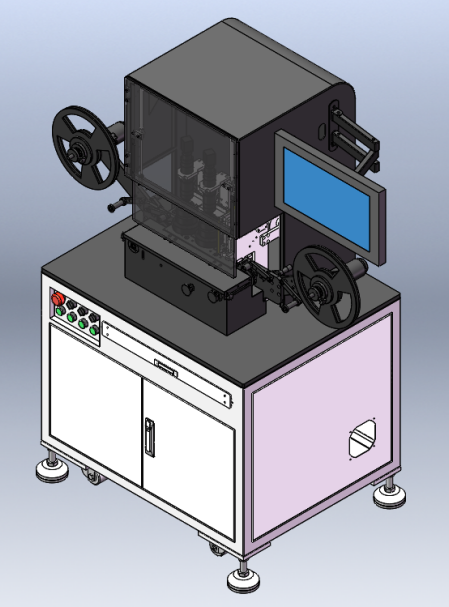

3. Standard machine with loading and unloading

Advantage Suitable for neat incoming materials, arranged into a whole plate of materials after inspection, large material storage, manpower saving, sound and light alarm in advance when the material is full, reminding to remove materials. Functional advantages: High effective to identify defects such as dark cracks, chipping, dirty blistering, scratches, missing corners, watermarks, deformation, shape (length, width, and height), and the production speed: 35000-180000 pieces/hour, we can customize the equipment for different request and wide range adaption.

4. tracked loader

Advantage: High effective to identify defects such as printing, presence or absence of material, rollove, chipping, stitch length, and poor tape sealing. Production speed: 60000-100000 pieces/hour.

Click here to pre-register to Exhibit Click here to pre-register to Visit

|