Shenzhen Zonben Testing and Control Co., Ltd specializes in the research and development and manufacture of motor testing equipment, from single supply of motor detection equipment to domestic white household appliance manufacturers, to providing complete solutions for world-famous automobile motor manufacturers. We have developed, prospered and expanded with the motor industry.

Three major series of professional products of the company: 1Ӣ Motor dynamometer (performance test of products such as rear scraper motor, DC motor whole system, AC motor, stepping motor, brush less motor, servo motor, etc.); 2Ӣ Hard support dynamic balance tester (automatic positioning dynamic balancing machine, brush less motor rotor dynamic balancing machine, etc.); 3Ӣ Special products (armature rotor spot welder monitor, vehicle window controller ECU tester, cogging torque tester, commutator surface quality tester).

Exhibits

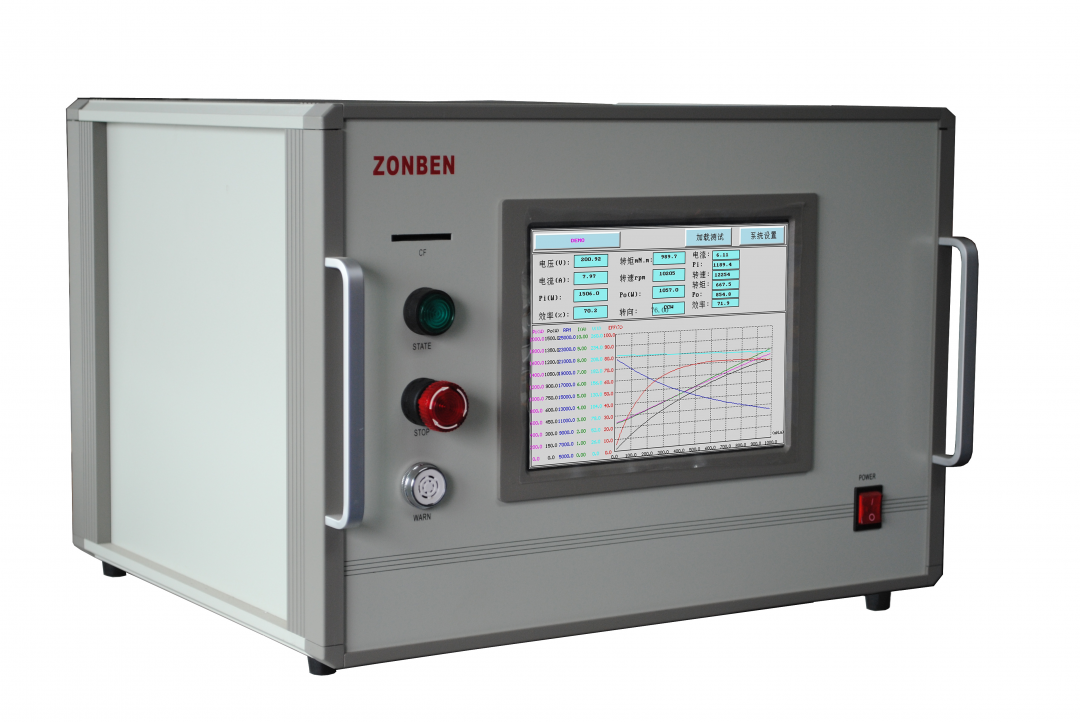

Hysteresis Dynamometer

This series of products integrate the motor dynamometer. The system can be used in test labs, at inspection stations, and on the manufacturing floors. With a Hysteresis Braking system, the Dynamometers do not require speed to create torque. It can provide a full motor ramp from free-run to locked rotor. The testing of free-run load-run could be finished in one operation.

Armature Rotor Test Instrument

The product is suitable for use in a brush motor armature rotor electrical performance testing, can achieve online for armature rotor production process to monitor the quality of the products, to completely eliminate commutator spot welding, winding interturn short circuit, winding insulation fault, such as product defects, can help the motor manufacturers to promote the reliability and consistency of the product.

The For Armature Commutator Test

The purpose of the commutator inspection unit is to detect armature parameters for making better quality after turning and detecting the turning faults, cutting tool worn-out, shaft unrondness, commutator faults, etc.

Click here to pre-register to Exhibit Click here to pre-register to Visit

|