Westmag Technology Corporation Ltd. Sichuan Westmag Technology Co., Ltd. Booth No.2531 www.chinawestmag.com

Company Profile Southwest China Institute of Applied magnetic technology in order to play its advantages Westmag technology developmentcompany founded in 1994, is the development of the Group of industries. The company mainly engaged in the rare-earth permanent magnetic materials and devices, soft magnetic materials and devices, microwave ferrite materials and devices, magnetic equipment, special instruments and systems development and production of permanent magnetic material within the professional research and production departments set up the whole magnet owned enterprises.

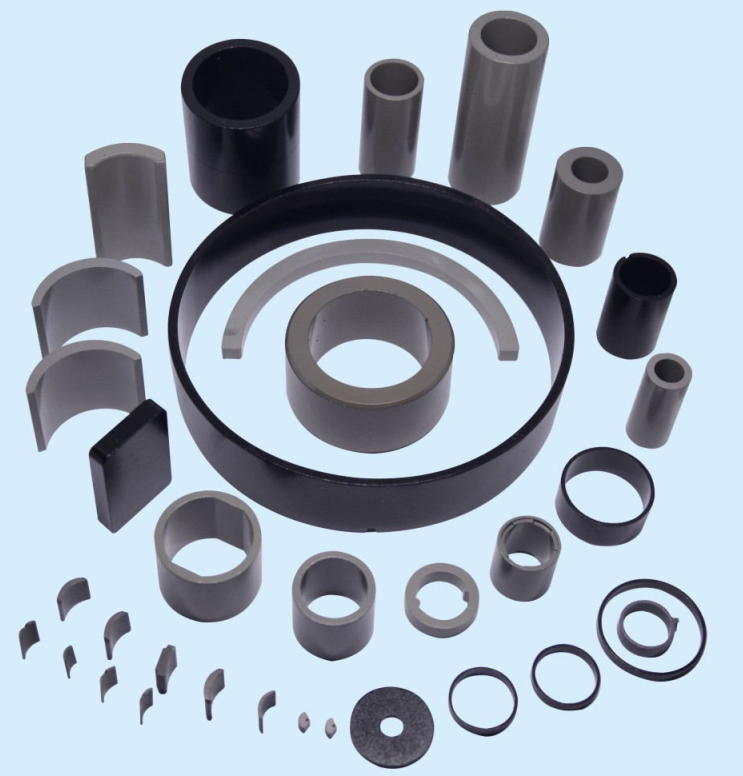

Exhibits 1. Molded bonded rare earth permanent magnet

Molding bonded rare earth permanent magnet is made of neodymium iron boron or samarium cobalt magnetic powder mixed with polymer material and molded into isotropic permanent magnet products of various shapes. Product features: the magnet with thin wall and complicated shape can be made into one time forming without processing;It can be magnetized in any direction, suitable for making radial, axial (end face) multipole or radial magnetized magnet.

2. Injection molding rare earth and ferrite permanent magnet

It is the use of neodymium iron boron, samarium cobalt, ferrite magnetic powder mixed with polymer materials, by granulating equipment into granule material, injection molding machine through mold molding for various shapes of isotropic and anisotropic permanent magnets and components.Various shapes of isotropic and anisotropic permanent magnets and components. Product features: one time molding does not need to be processed into magnets with complex shapes;It can be injection molded with the core and nesting of motor and other components together with magnets.Axial and radial orientation;Good oxidation resistance, no surface corrosion treatment.

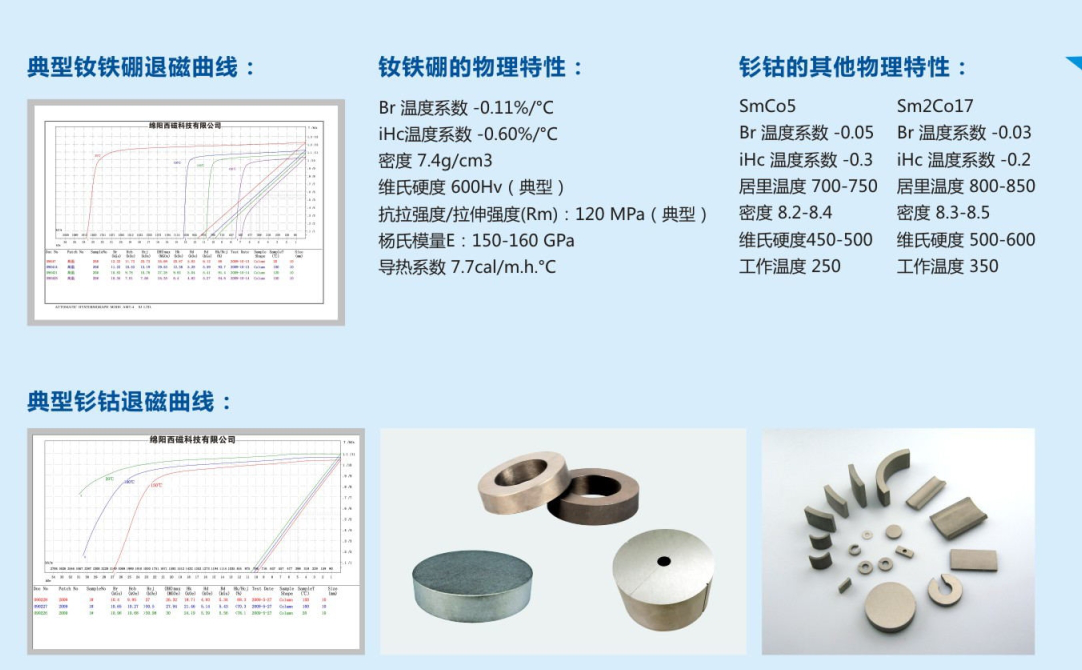

3. Sintered neodymium iron boron samarium cobalt permanent magnet

NdFeB permanent magnetic material has the characteristics of high energy deposition, high consistency, low weight loss, excellent corrosion resistance, good gel affinity and so on.The main surface treatment methods are zinc, nickel, silver, gold, phosphating or electrophoresis , Polymer vacuum gas phase deposition, etc. Samarium-cobalt permanent magnetic material has high magnetic energy product, very low temperature coefficient and high temperature resistance. Its service temperature can be up to 500¡ãC. It also has strong corrosion resistance and oxidation resistance.

Click here to pre-register to Exhibit Click here to pre-register to Visit

|